Following successful testing of the JimStim (well, making sure there was 12V where it should be and resistances change with twiddling the pots) I made a start on building the Megasquirt module proper. The comprehensive kit from

DIY Autotune comes extremely well packaged and labelled, identifying each component, its value and important assembly information such as leg bend length and if the part needs to stand off from the PCB. I would heartily recommend this company to anyone considering the purchase of a kit, or indeed anything related. Anyway, I had to make a start on this:

First job was a modification (I can't do anything the conventional way!). I am planning to use wasted spark, PWM Idle valve control, ECU controlled cooling fan relay and an 'engine running' signal, so it seemed logical to have an auxiliary PCB to tidy everything up. In addition, I am not keen on soldering wires into connectors for automotive applications since there is a risk, albeit small, of wire breakage from fatigue. The standard solder bucket DB37 connector will have to be replaced with an automotive spec crimped terminal part. I managed to stumble across an enclosure of similar footprint, but taller to allow all of the additions to be made so I procured it from Maplin (part number N85AL) and set about scheming the design. Fortunately, the enclosure manufacturer kindly makes 3D CAD models available, so this was a relatively easy job:

With this complete, I could make a start on trying to turn it into reality. Since the enclosure is metric (100mm wide slot opening) and the Megasquirt PCB is imperial (4 inches), I had a small amount of filing to get the two to mate together. This had to be done with great care to ensure the intermediate copper layers (it is a 4 layer PCB) were not shorted to the case. All appeared to be well:

This has a knock-on effect to the heatsink strip that sits under the power devices. I had to shave a small amount off this as well to get the holes to line up:

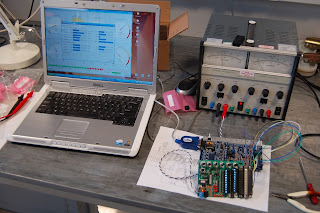

With this all fitting together, I can make a start on stage 1 of the controller - the power supply.